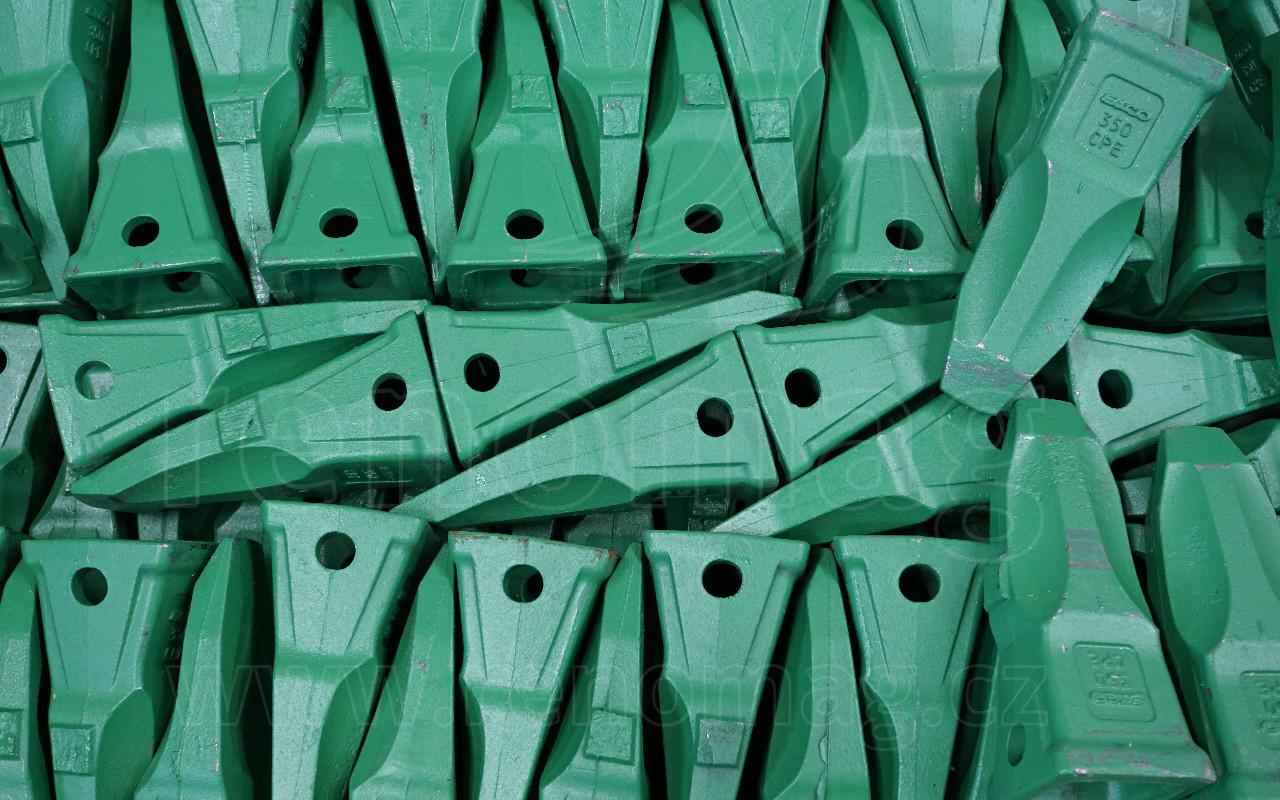

Esco MaxDRP Teeth

Our long-standing cooperation with ESCO® allows us supply to our partners state-of-the-art technology and premium products. The ESCO® company is a leading designer, developer and supplier of up-to-date abrasion-resistant tools and parts used in the mining, aerospace and power engineering industries and their infrastructure.

ESCO® was founded in Portland, Oregon, in 1913. For over one hundred years now the company has seen steady customer demand for its products in order to increase their productivity and make use of ESCO®'s professional services and innovative solutions to their vexing problems regarding wear and tear, impacts, corrosion and insufficient thermal resistance. Present in nineteen countries on six continents, the company operates a network of 28 manufacturing plants and 35 sale points and distribution centres.

The MaxDRP™ teeth from the relevant ESCO® programme can be attached directly to CAT® J adapters (i.e. those locked in place with a pin and ring).

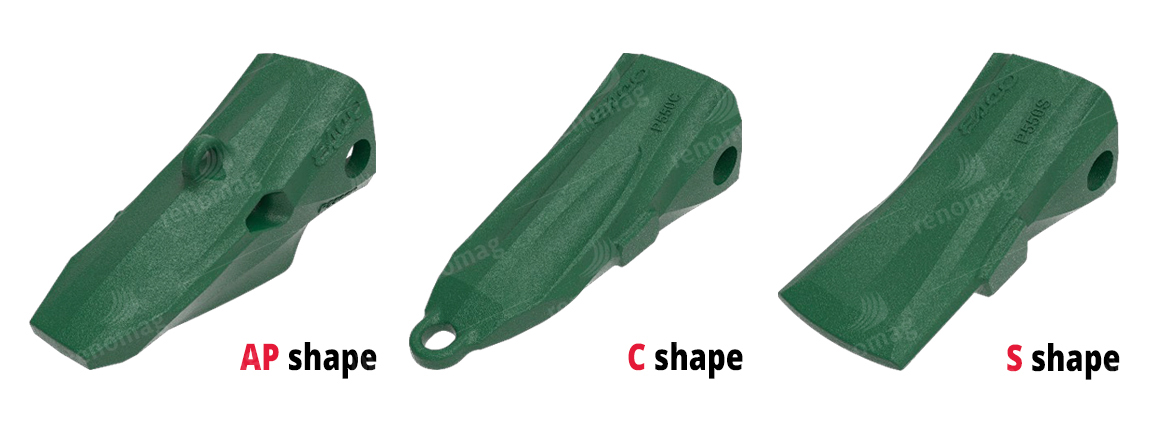

The teeth are designed for the best achievable:

- ability to penetrate

- wear and tear resistance

- utility

The benefits of MaxDRP™ teeth include the strengthened tooth body where the teeth rest on the adapter, a reinforced rib along the entire tooth length, and the wear indicator where the pin hole is reinforced to protect the pin.

MaxDRP™ Advantages:

- the stronger tooth body is more powerful and supports the self-sharpening feature

- cone-shaped tip for maximum penetrating capability

- tooth shape optimized to stay sharp

- reinforced bottom for longer service life

- widened rear section for better protection of the adapter

- cast from A92, a solid abrasion-resistant alloy

ESCO® INTRODUCES NEW HAMMERLESS MaxDRP™ PLUS REPLACEMENT POINTS for J450 and J550 sizes excavators and loaders.

Designed for safety and ease of use, the MaxDRP™ Plus system utilizes a standard tool on a unique pin and collar locking system, eliminating the need for swinging a hammer.

ESCO® Proprietary Alloys:

- Increased wear life

- Superior reliability

- Consistent performance

Caterpillar assemblies are easily converted to ESCO® points with no modification to the existing adapter. In addition, ESCO® alloys and point shapes provide up to 25% longer wear life for significantly reduced maintenance costs.

MaxDRP™ Plus Hammerless:

- Increased site safety

- Faster tooth replacement

- Reduced maintenance costs

New hammerless MaxDRP replacement points.pdf (1,02 MB)