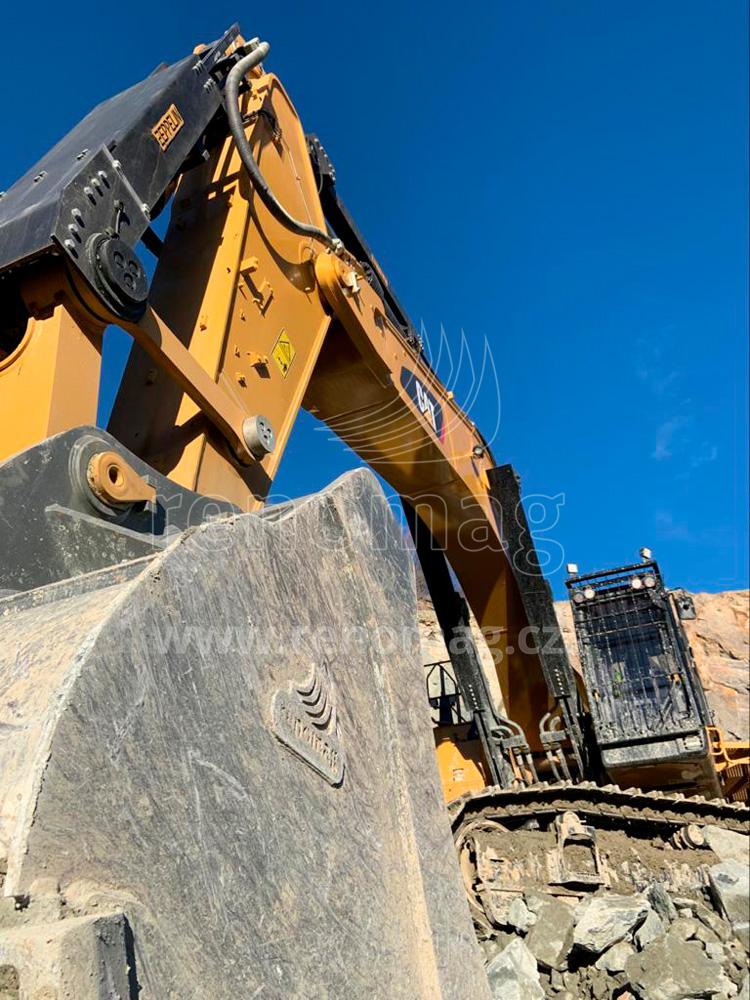

Buckets for machines above 50 tonnes

These buckets that we make of the best materials with emphasis on solidity and abrasion resistance are designated for bigger excavators operating on construction sites and in mines and quarries. Their design is optimized for a specific brand and type of the machine. Our custom-made buckets deliver great performance satisfying the customer’s requirements for economical, trouble-free and profitable machine operation. Certification Hardox® in My Body guarantees quality, reliability and long service life.

MAIN ADVANTAGES:

- Teeth system ESCO SV2® provides optimal excavation performance

- Shape for greater capacity and shorter distance between the pin and teeth for excavating power

- The bucket body made of abrasion resistant and solid materials and reinforced sides create greater structural integrity of the bucket design

- Strong abrasion resistant armouring of the bottom and additional cast elements to protect the lower parts of the sides

- Solid design of the suspension provides high solidity and endurance

- Easily detachable protective casings for the edge and sides, welded-on or TOPLOK®

- Two-part chromium-carbide supplementary parts of 700 HB hardness providing wear protection

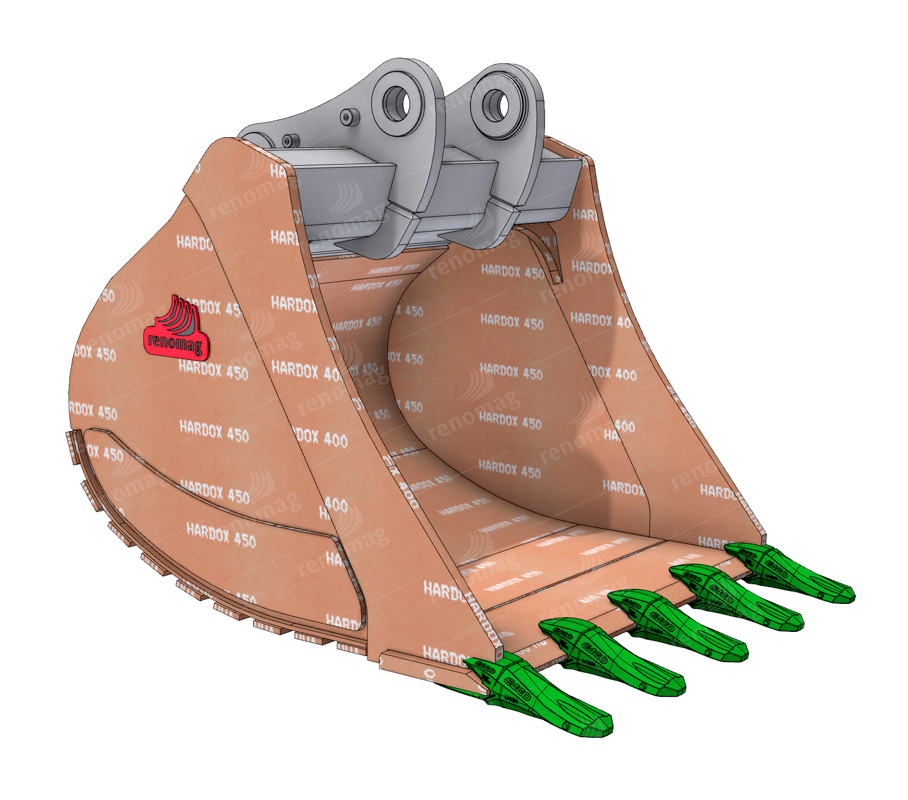

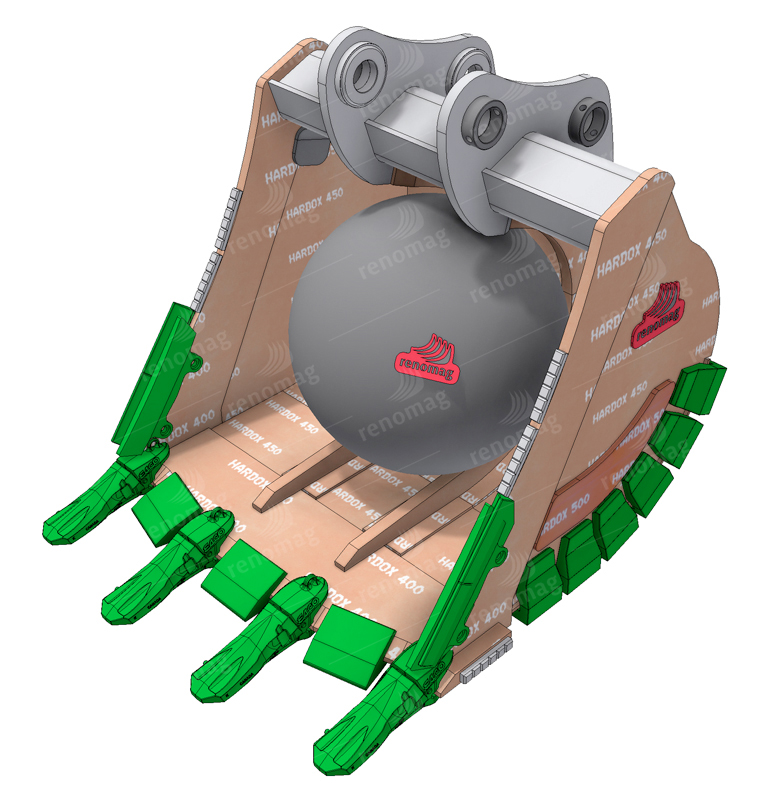

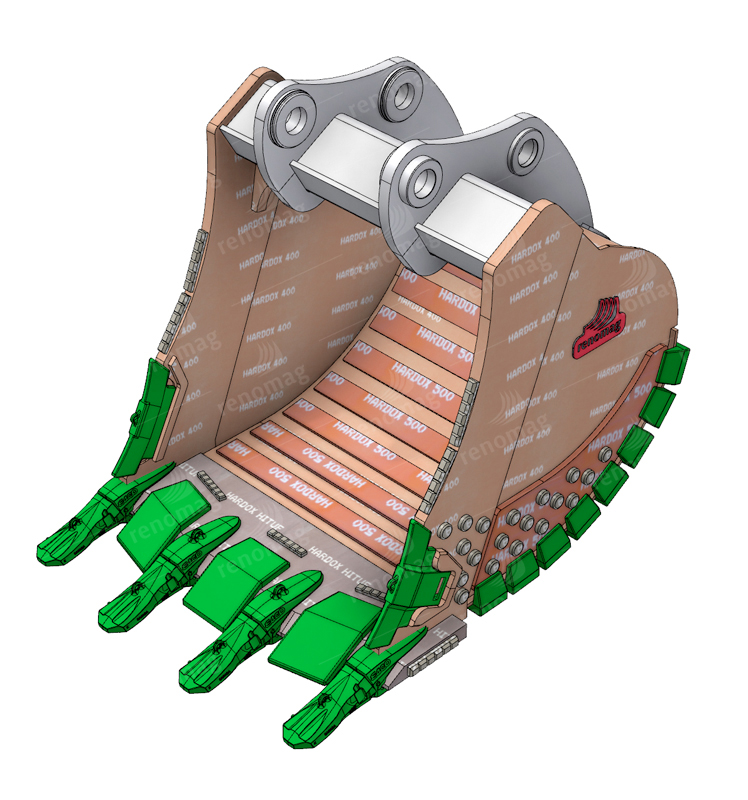

BUCKET HD

The reinforced bucket HD optimized for machines above 50 tonnes is ideally suited for earth moving and loading of materials of workability classes 4 and 5. It is designed for excavating in materials disconnectable with medium difficulty, such as heavy clay, soil mixed with sand or gravel, eroded or weathered granite, slate, marl, debris or frozen soil. In the strained areas its construction is reinforced and it is wear resistant, with its abrasion resistant bottom being reinforced with outer transverse plates; kinematics and the size of teeth are optimized for a specific excavator model.

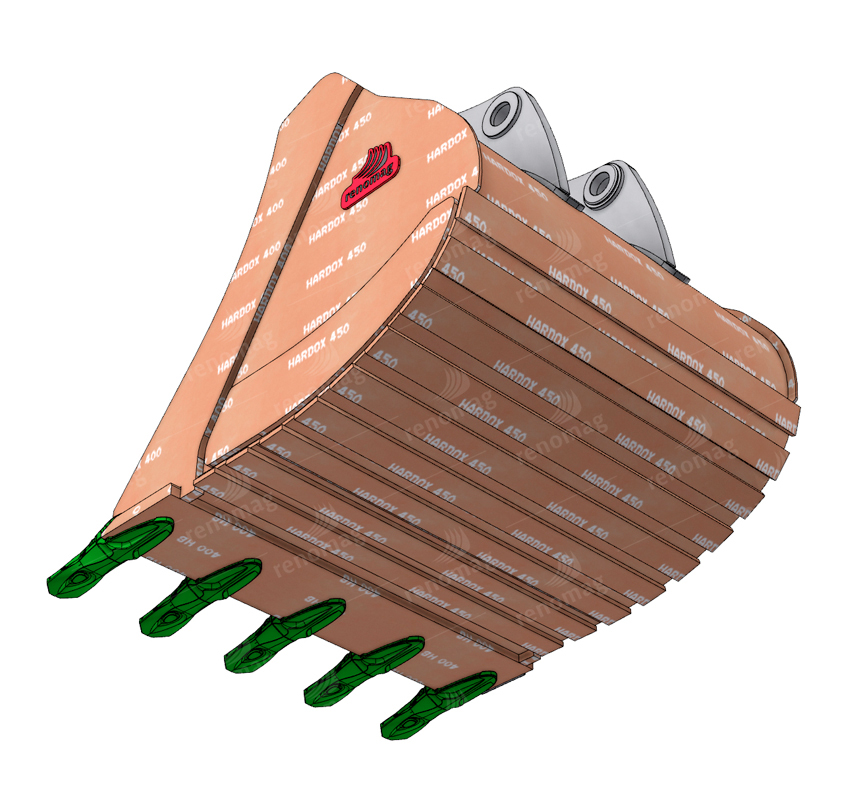

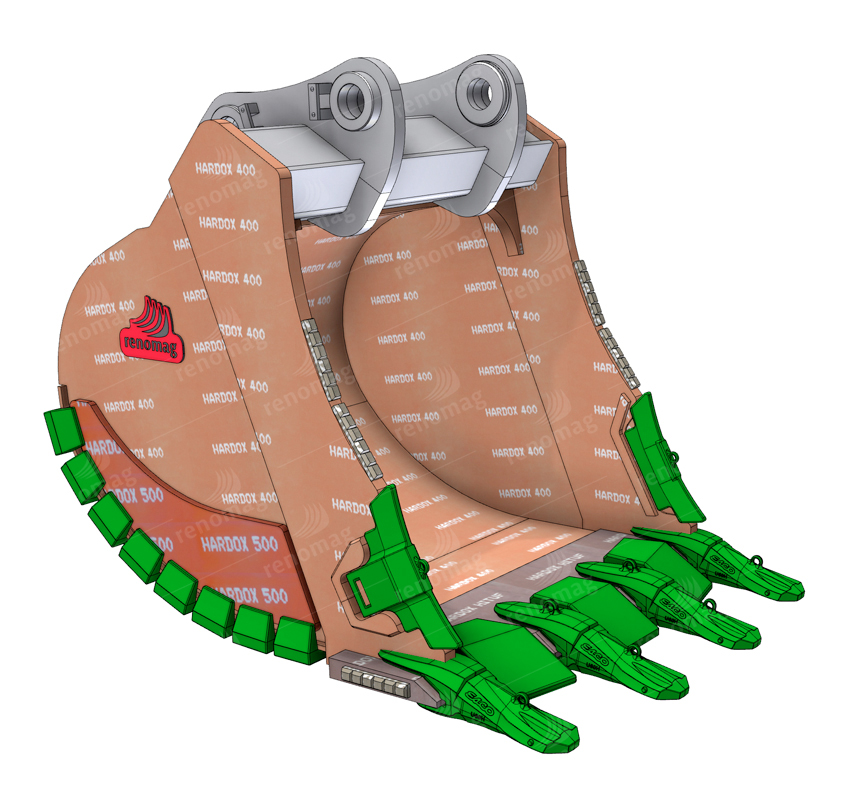

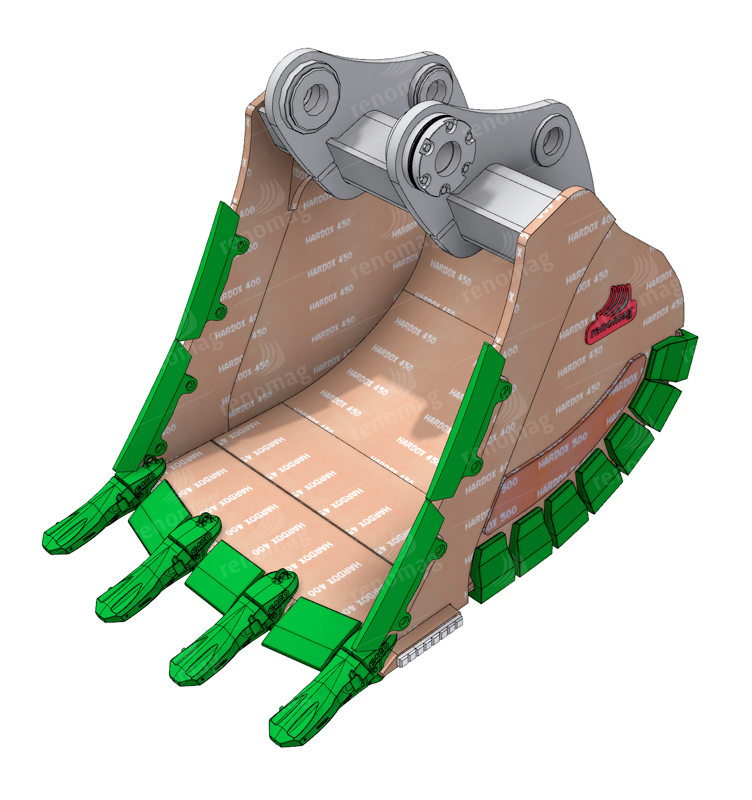

BUCKET XHD

The rock bucket XHD designed for machines above 50 tonnes is primarily intended for moving abrasive material from the fifth to higher classes of workability. It is particularly well suited for more demanding operation in stony soils and when handling disconnected rocks such as granite, basalt, sandstone and more. The bucket body is reinforced in the strained areas; the stronger edge with a teeth system and the shape are optimized for specific excavator models. The sides and bottom have strong abrasion resistant armouring fitted. The space of the edge between the teeth and the lower part of the sides are protected with weld-on or, on request, easily detachable cast elements, the upper part of the sides and the edge front with two part blocks of 700 HB hardness.

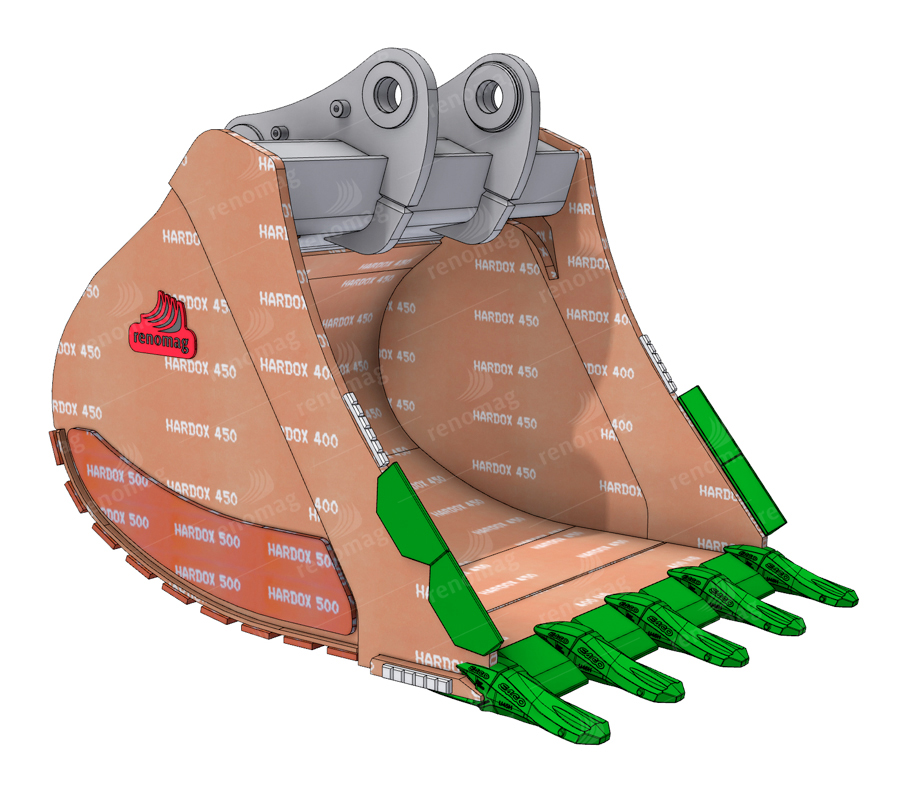

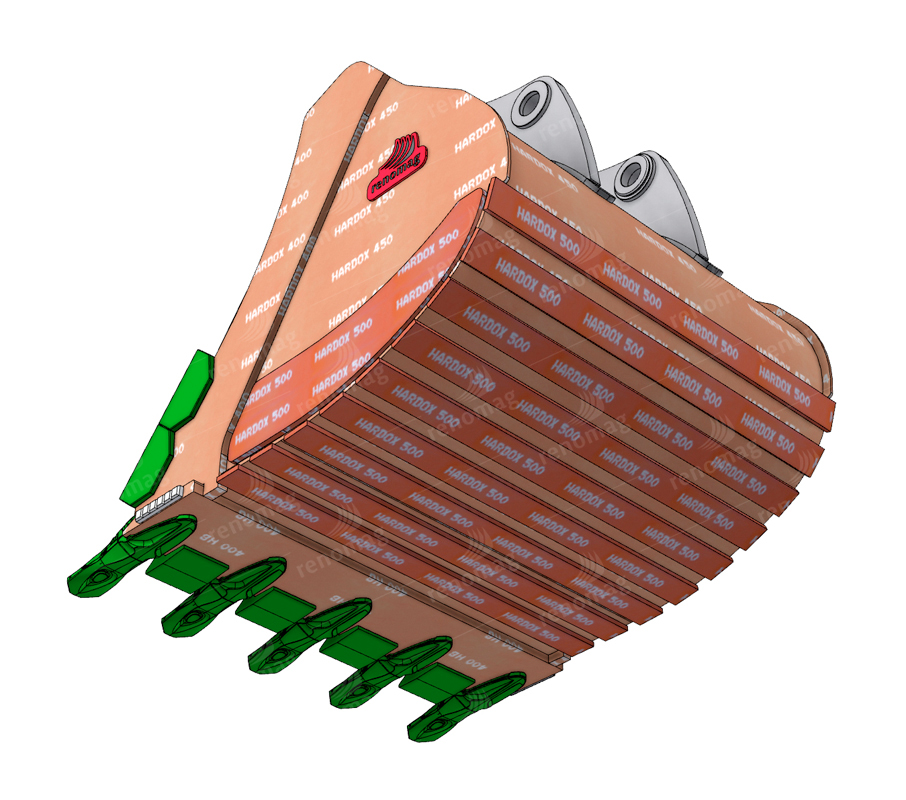

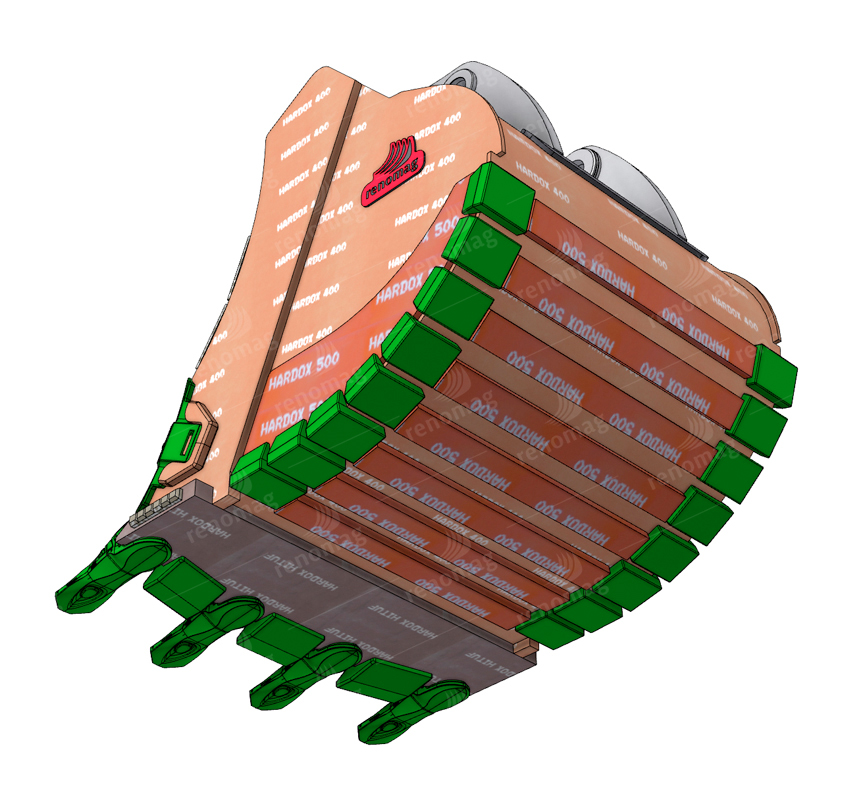

BUCKET XXHD

Extra rock buckets XXHD are produced for excavators above 50 tonnes engaged in the most demanding operations. They are designed for daily work with abrasive material of the fifth and higher class of workability, and with solid minerals of the seventh class of workability disconnectable with explosives, mainly in quarries. Their structure is reinforced, the stronger edge with a size-fitting teeth system and shape are optimized for specific excavator models. The sides and bottom are strongly protected against abrasion and in addition reinforced on the sides with cast abrasion resistant elements in the areas under greatest stress. The space of the edge between the teeth and the lower part of the sides are protected with weld-on or, on request, easily detachable cast elements, the upper part of the sides and the edge front with two part blocks of 700 HB hardness.The edge shape is straight, arrow-like or modified.

CUSTOM-MADE BUCKETS

As a rule we optimize buckets for machines above 50 tonnes based on customer specifications to satisfy their demands on work with different materials and further we adjust kinematics to a specific make and type of the customer‘s excavator with the aim of providing long service life, high performance and economical operation.

Renomag Excavator Buckets For Machines Over 50 Tonnes.pdf (2,8 MB)