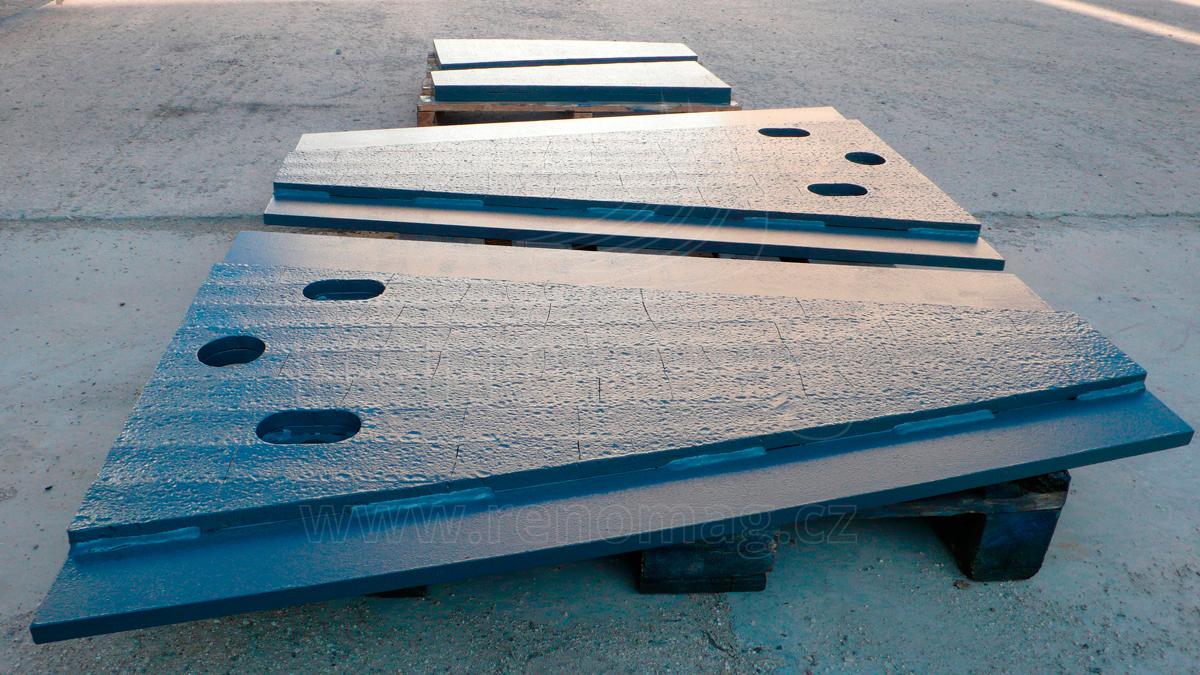

Composite plates with 600 HB overlay

Composite metal plates are hard-faced with a layer containing chromium carbide bound in composite material connected to a weldable underlay. Coated plate is known as one of the most abrasion resistant materials available. Compared to that of hardened steel, the wear life of composite plates has been proven to last up to ten times longer in highly abrasive conditions.

The standard underlay material of mild steel forms the base onto which the abrasion resistant overlay material is welded and whose structure contains chromium carbide grains in martensitic or austenitic modes, or in the combination of both.

The basic underlay material can also be used as a structural steel for manufacturing of e.g. hoppers or slides, so the whole product can be made completely of coated plate.

Composite plates are available in several different classes so as to satisfy requirements for various operating environments:

- XR2355 – Suitable for high abrasion and impact strain operating conditions. Austenitic structure of chromium carbide grains.

- XR2455 – Suitable for high impact strain operating conditions. Combination of austenitic and martensitic structures of chromium carbide grains.

- XR2560 – Suitable for high frictional abrasion applications, for the fine-grained particle environment with low impact strain. Martensitic structure of chromium carbide grains.

Hardness of composite overlay expressed by the Brinell scale:

- Hardness of composite plates ≥ 600 HB (≥ 58 HRC)

- Abrasion resistance is for the most part due to presence of carbides Cr, Mn and Si in appropriate proportion.

We supply material in the following thicknesses:

| Code | Thickness of abrasion resistant overlay | Total thickness | Weight per 1m2 |

| XR4ON6 | 4 mm | 10 mm | 77 kg |

| XR6ON6 | 6 mm | 12 mm | 92 kg |

| XR5ON8 | 5 mm | 13 mm | 100 kg |

| XR6ON8 | 6 mm | 14 mm | 108 kg |

| XR5ON10 | 7 mm | 15 mm | 116 kg |

| XR9ON10 | 9 mm | 19 mm | 146 kg |

| XR12ON12 | 12 mm | 24 mm | 162 kg |

| XR17ON12 | 17 mm | 29 mm | 222 kg |

Other models can be supplied on request.