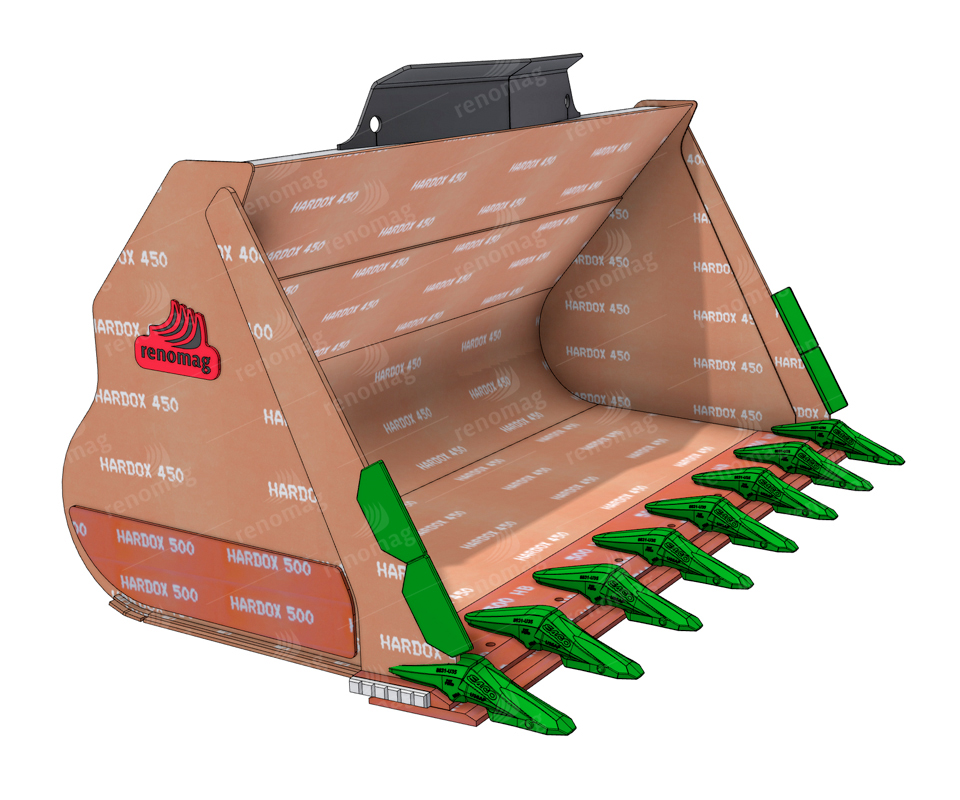

Reinforced HD buckets for loaders

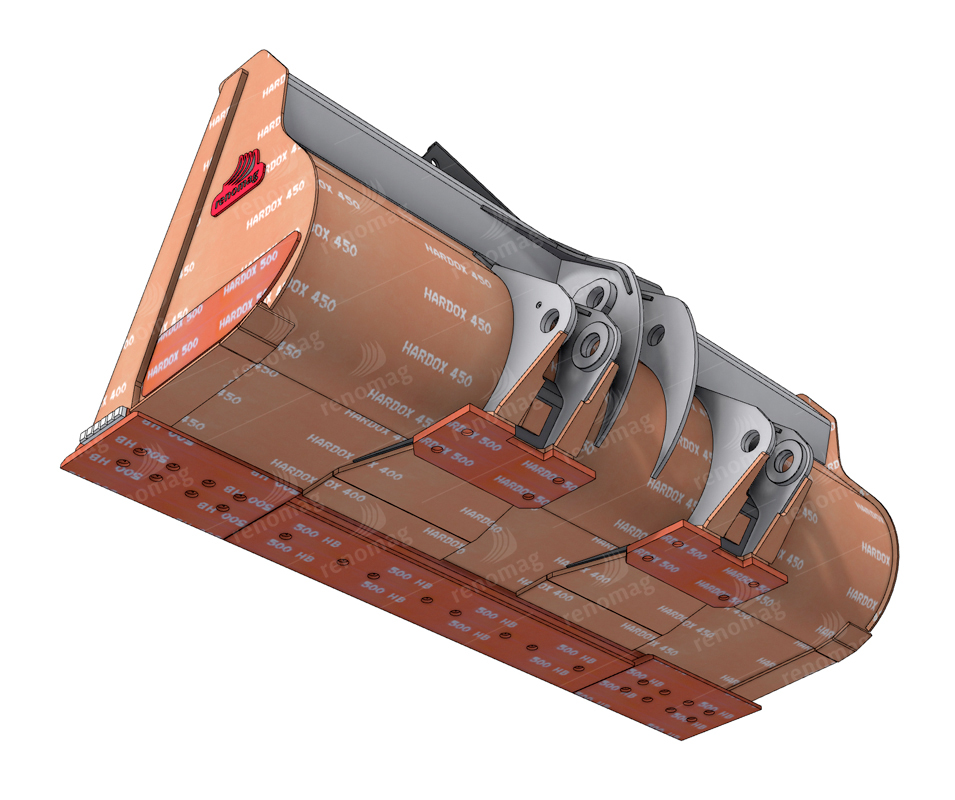

Reinforced heavy duty HD buckets for loaders are designed for use in demanding conditions at demolitions, building and disposal of the mined material. These dippers from solid and abrasion resistant material have a proven shape optimized for minimum resistance while penetrating material and for easy dipper loading. The bottom of the wedge-shaped cross-section transfers the breaking power of the loader without losses. The dipper suspension is firmly connected to the reinforced upper part and through the design of the bottom with the edge. This model transfers the machine’s performance efficiently, prevents the dipper body from bending and protects suspension parts against wear. Certification Hardox® in My Body guarantees quality, reliability and long service life.

Reinforced HD loader buckets are supplied in models with a screwed detachable edge or with teeth, replaceable or welded-on protective segments between the teeth on request.

Main Advantages:

- ESCO® Ultralok teeth system provides optimal loading performance

- Optimized for maximum use of the machine’s performance

- Reinforced sides and bottom, all parts of the dipper made of solid abrasion resistant material providing long service life

- Replaceable weld-on abrasion resistant plates for bottom protection

- The solid suspension design provides high bending resistance

- The wedge-shaped bottom directs material movement for quick load and tipping with adamant transfer of the excavation power, while the flat bottom for easier penetration is designed for use in expedition machines and loose materials (*this choice is only possible for selected types and brands of loaders)

- Can be supplied with complementary parts preventing wear or protecting against high temperatures.

Renomag Reinforced HD Loader Buckets.pdf (880 KB)