ITR Rubber Tracks

ITR rubber tracks were designed, constructed and manufactured using the most advanced technologies aimed at providing outstanding levels of quality and resilience when used for mini excavators, tracked skid steer loaders and small dumpers. Many years of experience, numerous field trials and tests within designing contributed to the development of a continuous rope system which is currently used in all the ITR rubber tracks. The technologies with continuous ropes combine resistance, flexibility and firmness throughout the rubber track framework, it reduces wear levels and improves efficiency during operation.

The rubber structure completes and provides high protection of the system of ropes and internal steel elements which make up the supporting structure. The strong rubber layer absorbs impacts and protects the metal structure from impacts.

CHARACTERISTICS

- Internal parts of forged steel

- Ropes of greater thickness

- High resistance to scratches and wear

- Reduced noise and vibrations

- Low pressure on terrain

- Easy changeover to steel tracks

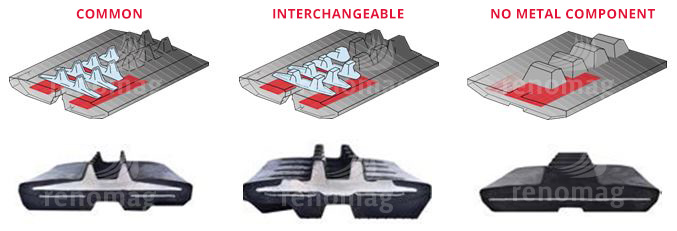

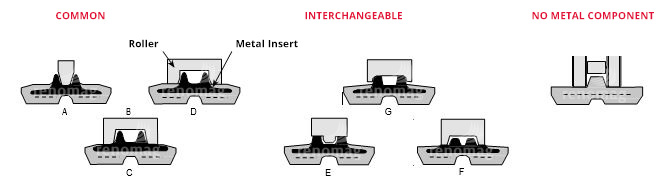

COMMON TRACKS

Common tracks can be used on tracked undercarriages designed for operation with only rubber tracks. In the case of using common tracks traversing rollers only come in contact with metal guiding for the purpose of guiding provision while they prevent getting out of track. This type of tracked undercarriage cannot use steel chains.

INTERCHANGEABLE TRACKS

Interchangeable tracks can be used on undercarriages designed for operation with rubber or steel tracks. When interchangeable tracks are used, traversing rollers are in contact with a rubber track in the same way as in the case of a steel chain.

NO METAL COMPONENT TRACKS (NMC)

These tracks do not contain any metal reinforcements and are made up of a series of firm ropes protected by a very strong rubber structure. The lightweight framework enables greater flexibility of the track, while the great width of the tread provides higher traction without compromising surface adherence.

ANTI VIBRATION TRACKS (AV)

Anti vibration tracks contain a metal insert with an innovated shape for guiding, aimed at reducing vibrations and an overall track weight, thereby guaranteeing equal resilience and reliability. Anti vibration tracks moving on rollers in constant contact whereby minimizing vibrations.

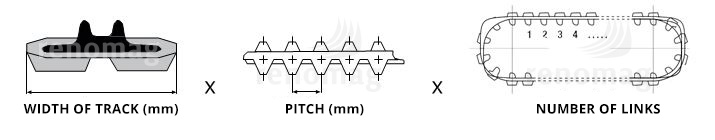

IDENTIFICATION OF TRACK SIZES

Tracks are identified based on three basic dimensions: width of track, pitch and number of links.

You can rely on getting the right size for your particular machine.

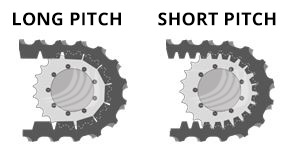

TYPES OF PITCHES

The essential dimension of a rubber track is its pitch. Pitch is the distance between the centres of two successive metal inserts. Pitch serves as a measure for identifying tracks as long pitch (i.e. rubber tracks whose metal guides engage with every other tooth of the gear) and short pitch tracks (i.e. rubber tracks whose metal guides engage with each tooth of the gear). These tracks are also known as 'Step short' rubber tracks (or half pitch tracks).

TYPES OF GUIDES

EXAMPLES OF INDICATIONS OF TYPES OF ITR RUBBER TRACK GUIDES

| WIDTH | PITCH | NAVIGATION SYSTEM | SIZE (mm) | MAXIMUM LOAD OF MACHINE | |||||

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | ||||||||

| - | 1 | 2 | 3 | 4 | 5 | 6 | kg | ||

| 150 | 72 | A | 65 | 46 | 39 | 23 | 23 | 21 | 500 |

| 180 | 60 | B | 61 | 54 | 32 | 25 | 20 | 22 | 500 |

| 180 | 72 | A | 70 | 51 | 38 | 24 | 29 | 30 | 700 |

| 180 | 72K | C | 64 | 53 | 40 | 21 | 22 | 20 | 700 |

| 190 | 72 | A | 68 | 50 | 38 | 21 | 28 | 27 | 800 |

| 200 | 72 | A-B | 76 | 56 | 40 | 23 | 28 | 26 | 1200 |

| 200 | 72K | C | 71 | 53 | 39 | 23 | 30 | 29 | 1200 |

| 230 | 72 | A | 82 | 57 | 40 | 24 | 30 | 26 | 1400 |

| 250 | 72 | A-B | 82 | 57 | 40 | 24 | 30 | 26 | 1600 |

| 320 | 84 | C | 96 | 82 | 60 | 46 | 48 | 34 | 4500 |